Cotton Irrigation

Related Articles

- Fertilizing Cotton with Poultry Litter 5

- Mississippi Cotton Insect Situation of 2010: A Look Back 3

- Bayer CropScience-O.A. Cleveland Weekly Cotton Commentary 0

Latest Tweets

Rainfall has minimized the need for cotton irrigation in many areas up to this point. Some areas between Clarksdale and Tunica and isolated areas in the south Delta are dry and have irrigation water running. As everyone knows, cotton irrigation is not a cut and dry process. In simplistic terms, cotton growth stage and soil moisture status drive our irrigation decisions. One of these – cotton growth stage – is pretty straightforward. Our recommendation is to ensure that your soil profile has adequate moisture as cotton begins to bloom. Water and nutrient demands increase when cotton begins to bloom and these demands tend to top out at or shortly after peak bloom (3-4 weeks after first bloom).

Soil moisture status is a somewhat more complicated matter. For years, we have made irrigation decisions using one or all of the following: experience, a pre-determined schedule, and/or digging a hole and observing moisture levels as well as other methods. Over the past five years (give or take), there has been tremendous emphasis placed on use of soil moisture sensors to determine soil moisture status and determining irrigation needs using these sensors. Two types of sensors are commonly used to monitor soil moisture status. Soil matric type sensors (i.e. WaterMark, etc.) measure the force with which water is pulling away from the sensor. Based on MSU data, we recommend triggering irrigation when a weighted sum from these type of sensors reach -90 kPa.

For example, if you have sensors at 6″, 12″, 24″, and 36″ depths and have readings of -125, -90, -60, and -20kPa, respectively, then the following would be used to determine the weighted sum. Your 6″ sensor is measuring moisture in 17% of the total depth of soil profile (6/36 = 17%) and your sensor reading was -125 kPa; therefore, -125 * 17% = -21 kPa. The 12″ sensor is also measuring moisture in 17% of the total depth of the soil profile and your sensor reading was -90 kPa; therefore, -90 * 17% = -15 kPa. The 24″ sensor is measuring moisture in 12″ (24″ – 12″) of the total depth of the soil profile which is equivalent to 33% (12/36) of the total depth of the soil profile and your reading was -60 kPa; therefore, 33% * -60 kPa = -20 kPa. The 36″ sensor is measuring moisture in 12″ (36 – 24″) of the total depth of the soil profile which is equivalent to 33% and your reading was -20 kPa; therefore, 33% * -20 kPa = -7 kPa. When you add all of your final readings: 21+15+20+7 = -63 kPa – this soil would not require irrigation at this time because the threshold of -90 kPa has not yet been reached.

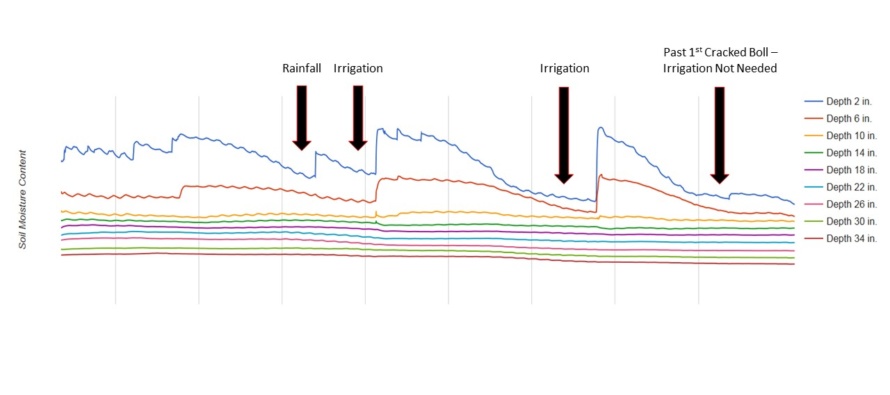

Capacitance sensors (i.e. Decagon, etc.) measure volumetric water content. Readings from these sensors can be somewhat more difficult to interpret. If you have a noticeable decline in soil moisture you can make a determination of when to trigger irrigation (see picture below). However, if there are no noticeable step downs in volumetric water content, determining when to trigger irrigation is much more difficult. In some silt loam “cotton” soils, it is not uncommon to not see a step down reduction in volumetric soil moisture content but rather a wave like response. In these situations, you must rely on experience and knowledge of your crop to determine when to irrigate.

Let me tell You a sad story ! There are no comments yet, but You can be first one to comment this article.

Write a comment